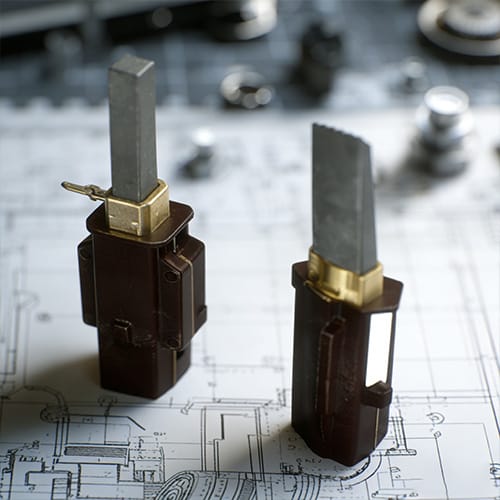

Carbon brushes are critical components in electric motors, generators, and various rotating electrical equipment, responsible for transmitting current between stationary and rotating parts. Despite their small size, their performance directly affects the efficiency, reliability, and lifespan of the entire equipment. For professionals in industrial manufacturing, new energy vehicles, home appliances, and other fields, choosing the right carbon brush and mastering proper maintenance methods are key to reducing operational costs and avoiding unexpected downtime. In this blog, we will break down the core knowledge of carbon brushes to help you make informed decisions.

1. Key Factors for Choosing the Right Carbon Brush

Not all carbon brushes are the same—selecting the appropriate type requires matching the product to the specific working conditions of your equipment. Here are the four most important factors to consider:

1.1 Material Type: Matching Performance to Application

Carbon brushes are mainly made of graphite, carbon-graphite, electro-graphite, and metal-graphite composites, each with unique properties:

- Graphite Brushes: Low friction coefficient and good lubricity, suitable for low-load, high-speed equipment such as small household appliance motors (e.g., washing machines, fans). They generate less wear on the commutator but have lower current-carrying capacity.

- Carbon-Graphite Brushes: Balanced wear resistance and conductivity, ideal for medium-load industrial motors (e.g., conveyor belts, pumps). They perform stably in normal temperature and humidity environments.

- Electro-Graphite Brushes: High-temperature resistance and strong current-carrying capacity, designed for heavy-duty equipment like high-power industrial motors, rail transit traction motors, and wind turbine generators. They can withstand extreme working conditions such as high vibration and high temperature.

- Metal-Graphite Brushes: Added with copper or silver powder to enhance conductivity, suitable for low-voltage, high-current applications such as automotive starter motors and EPS systems. They ensure reliable current transmission even in low-temperature environments.

1.2 Size and Shape: Ensuring Perfect Fit

The size and shape of the carbon brush must match the brush holder and commutator of the equipment. A mismatch can cause poor contact, increased sparking, and accelerated wear. For standard equipment, you can choose off-the-shelf products; for old or customized equipment, it is recommended to select manufacturers that provide customized carbon brush services to ensure precise fitting.

1.3 Working Conditions: Adapting to Harsh Environments

Consider the environmental conditions where the equipment operates: high temperature, low temperature, humidity, dust, vibration, etc. For example, carbon brushes used in offshore wind turbines need to have corrosion-resistant and waterproof properties; those used in desert areas require dust-proof and high-temperature resistant designs; and automotive carbon brushes must withstand frequent start-stop and vibration.

2. Daily Maintenance Tips for Carbon Brushes

Proper maintenance can extend the lifespan of carbon brushes and improve the stability of equipment operation. Here are three key maintenance points:

2.1 Regular Inspection of Wear Level

Check the wear of carbon brushes regularly—when the wear amount exceeds 2/3 of the original length, replace them in time. At the same time, check the contact surface between the carbon brush and the commutator: the contact area should be more than 70% to ensure good current transmission. If there are uneven wear or scratches, grind the carbon brush surface to fit the commutator.

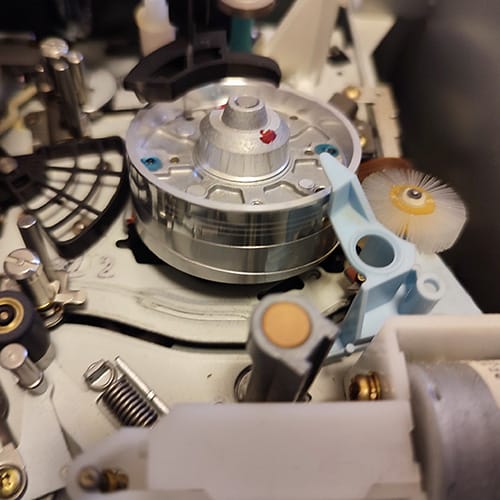

2.2 Keep the Brush Holder and Commutator Clean

Dust, carbon powder, and oil stains accumulated in the brush holder and on the commutator will affect the contact performance of carbon brushes. Clean the brush holder regularly with a soft brush or compressed air, and wipe the commutator surface with a clean cloth dipped in alcohol to remove dirt and oxidation layers.

2.3 Check the Spring Pressure

The spring pressure of the carbon brush affects the contact stability. If the pressure is too low, the carbon brush will vibrate and generate sparks; if the pressure is too high, it will accelerate wear. Regularly check the spring for deformation or fatigue, and replace it if necessary to ensure that the pressure is within the normal range.

3. Why Choose Professional Carbon Brush Manufacturers?

Many enterprises often choose low-cost carbon brushes to save costs, but this may lead to frequent replacement, increased equipment downtime, and even damage to the commutator and motor, resulting in higher maintenance costs. Choosing a professional carbon brush manufacturer has three core advantages:

- Customized Solutions: Professional manufacturers can tailor carbon brush materials, sizes, and structures according to the specific needs of your equipment and working conditions, ensuring optimal performance.

- Reliable Quality Control: Strict quality inspection processes (such as wear resistance tests, high-temperature tests, and vibration tests) ensure that each batch of products meets industry standards and has stable performance.

- Professional Technical Support: Provide technical consultation, installation guidance, and after-sales service to help you solve problems encountered in selection and use, and reduce the risk of improper selection.

4. Conclusion

Choosing the right carbon brush and doing a good job in daily maintenance are essential for ensuring the efficient and stable operation of electrical equipment. Whether you are engaged in industrial manufacturing, new energy vehicles, home appliances, or other fields, it is crucial to cooperate with professional carbon brush manufacturers to obtain customized solutions and reliable products.

If you have questions about carbon brush selection, customization, or maintenance, welcome to contact our technical team. We have rich experience in carbon brush R&D and application, and will provide you with professional solutions tailored to your needs.