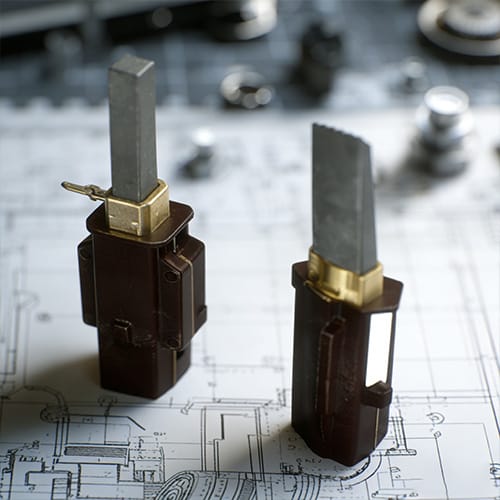

Carbon brushes may be tiny components in electric motors, generators, and rotating equipment, but their role is non-negotiable—they’re the bridge that transmits current between stationary and moving parts. A subpar carbon brush can lead to motor inefficiency, frequent breakdowns, and skyrocketing maintenance costs. For industries ranging from manufacturing to automotive and home appliances, choosing the right carbon brush and maintaining it properly is a game-changer. This guide breaks down the essentials to keep your equipment running smoothly.

1. Choose the Right Carbon Brush: 3 Key Factors

Not all carbon brushes are created equal. The right pick depends on your equipment’s operating conditions and performance needs.

Material Matters Most

Carbon brush materials dictate their durability, conductivity, and suitability for specific applications:

- Graphite Brushes: Low friction and excellent lubricity, ideal for low-load, high-speed devices like household appliance motors (washing machines, fans). They’re gentle on commutators but have limited current-carrying capacity.

- Metal-Graphite Brushes: Blended with copper or silver, these brushes boost conductivity—perfect for low-voltage, high-current scenarios like automotive starters and EV EPS systems. They perform reliably even in extreme temperatures.

- Electro-Graphite Brushes: Processed at high temperatures for superior heat resistance and wear performance, they’re built for heavy-duty industrial motors, rail transit traction systems, and wind turbines that face constant vibration and high loads.

Match Size and Shape to Your Equipment

A poor fit equals poor performance. Ill-sized brushes cause sparking, uneven wear, and premature failure. For standard motors, off-the-shelf brushes work fine. For custom or legacy equipment, opt for manufacturers that offer tailored solutions to ensure a precise match with your brush holder and commutator.

Consider Operating Environment

Harsh conditions demand specialized brushes:

- Humid/Marine Settings: Choose corrosion-resistant brushes to prevent rust and degradation.

- High-Temperature/Dusty Areas: Go for heat-stable, dust-proof designs to avoid clogging and overheating.

- Automotive Applications: Prioritize vibration-resistant brushes that handle frequent start-stops without losing contact.

2. Simple Maintenance Tips to Extend Brush Lifespan

Proper upkeep can double your carbon brush’s service life and cut downtime. Follow these easy steps:

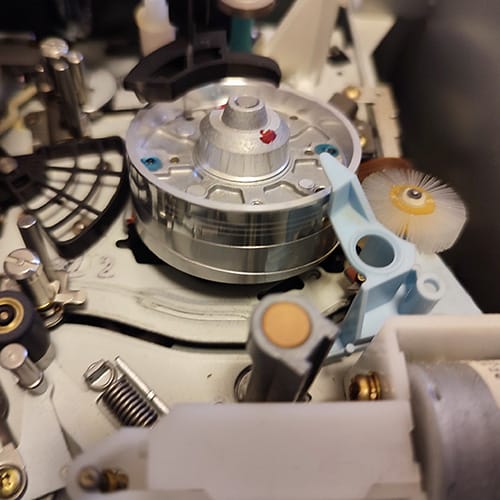

- Inspect Wear Regularly: Replace brushes when they wear down to 1/3 of their original length. Check that the brush-commutator contact area covers at least 70%—grind the brush surface if needed for a tight fit.

- Keep It Clean: Wipe commutators with alcohol-soaked cloths to remove carbon dust and oil buildup. Use compressed air to clear debris from brush holders—clogged holders cause poor contact and sparking.

- Check Spring Pressure: Too little pressure leads to vibration; too much accelerates wear. Replace worn or deformed springs to maintain consistent pressure.

3. Why Partner with a Professional Carbon Brush Supplier?

Cutting costs on cheap, generic brushes often backfires—you’ll end up replacing them frequently and risking motor damage. A reputable supplier offers three unbeatable benefits:

- Custom Solutions: They tailor brush materials, sizes, and designs to your exact equipment needs, not a one-size-fits-all approach.

- Rigorous Quality Testing: Every batch undergoes wear, temperature, and vibration tests to ensure it meets industry standards.

- Expert Technical Support: From selection advice to installation guidance, their team helps you avoid costly mistakes and optimize performance.

Final Thoughts

Carbon brushes may be small, but they’re the backbone of your motor’s performance. By choosing the right material, ensuring a perfect fit, and sticking to a regular maintenance routine, you can minimize downtime and maximize equipment lifespan.

If you need help selecting or customizing carbon brushes for your industrial or automotive applications, our team of experts is here to assist. Contact us today for tailored solutions that deliver results.